Clean energy from water

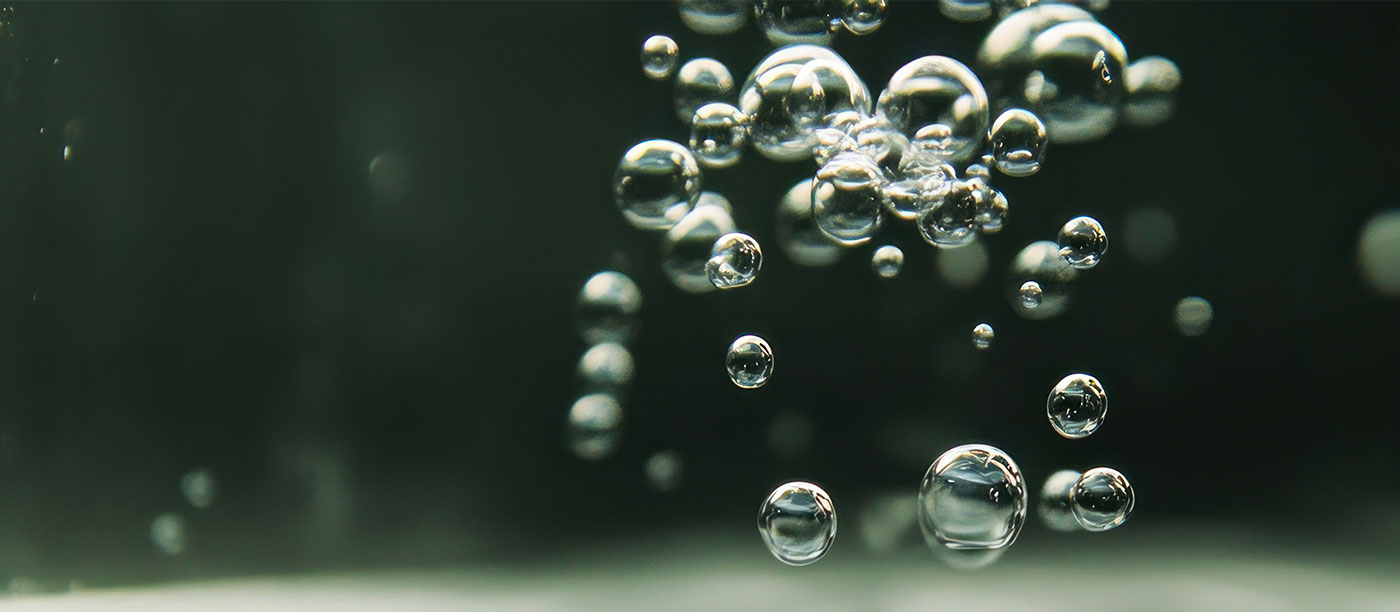

PEM electrolyzers use a process known as electrolysis to split water molecules into clean hydrogen that can be used in on-site applications ranging from industrial feedstock to transportation to power generation. Making hydrogen doesn’t get cleaner than this. The electrolysis process is essentially a fuel cell running in reverse. The only inputs needed? Water and electricity.

H₂Only

Water is purified via a reverse osmosis process and electrodeionization, while the AC electricity is converted to DC for operating and managing our electrolyzer cell stack assembly (CSA) system.

From water to hydrogen and oxygen

The CSA then uses the electrochemical process of water electrolysis to separate the oxygen from the hydrogen in the water. We ensure optimal stack performance, durability, and longevity through mixed resin beds that continuously recirculate the purified water throughout the process.

Five 9s of pure

Finally, hydrogen produced from the electrochemical cell stacks is dried and further purified to over 99.999% using our hydrogen purification system (HPS), making it suitable for fuel cell applications.

The hyaxiom difference

The flexible design of PEM Electrolyzer makes multi-MW scale-up simple and straightforward. System and production costs are reduced with integrated sub-assemblies for water treatment, hydrogen processing, purification, and power control.

Why choose HyAxiom PEM Electrolyzers

Flexible production

An adaptable balance of plant and electrical architecture.

Any source. Lower cost

Our high system efficiency means better economics for you. And with flexible operations, you can optimize your connection to all power sources, including intermittent renewables.

Hydrogen that works everywhere

HyAxiom’s system includes a hydrogen purification system (HPS), so you always produce hydrogen of the highest purity and suitable for any application.

Longer life means lower maintenance

With an industry-leading stack and system lifetime, you’re guaranteed long, reliable operations with minimal maintenance costs.

Scalable. Modular. Easy.